Conventional & Advanced Ultrasonic Testing

This technique is used to detect internal flaws within components by sending short wavelength sound waves of high and low frequency into the test material. This method can be used on a range of base materials, most commonly steel, but other metals and alloys can be as well.

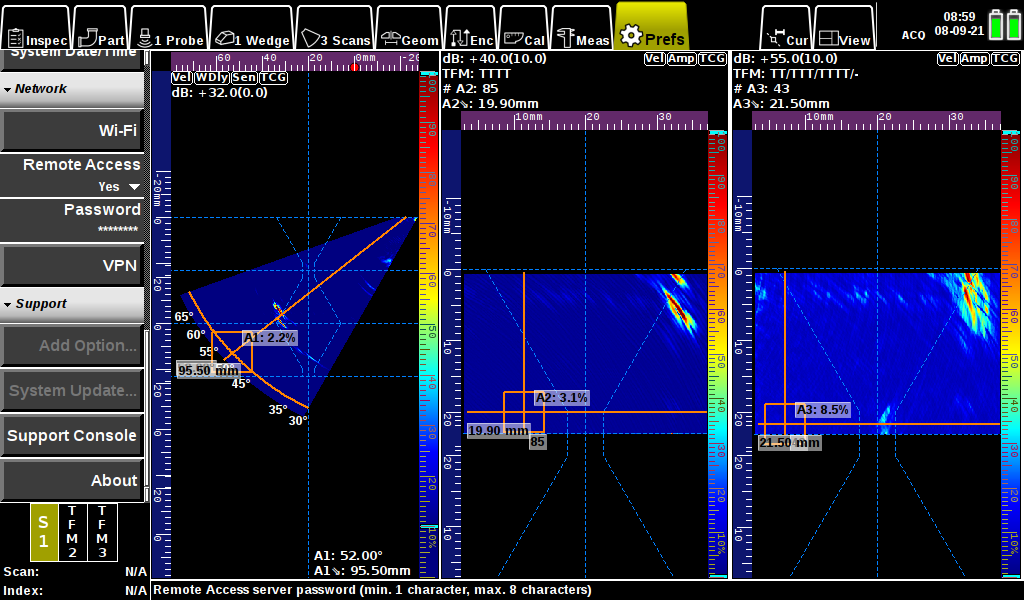

Ultrasonic sound waves are typically introduced into the item under test via an ultrasonic source, coupling media and hand held probe. As the sound travels through the item, reflected echoes return from the back surface and any internal discontinuities will reflect the sound, generating a signal identified on the monitor. The thickness of a material and location/distance of any present flaws can also be determined via calculation of the echo time lags recorded.

Scotia NDT can perform conventional and advanced ultrasonic testing on large or small components at our test facility or on site utilising the very latest portable, fully calibrated, flaw detectors from Sonatest.

Phased Array (PAUT) is an advanced method of Ultrasonic Testing that has many applications industrial sectors of Non-Destructive Testing.

Typical applications for PAUT are corrosion mapping of tank shells and weld inspection such a pipeline butt welds.

Phased Array Ultrasonic testing provides a high degree of accuracy when determining the size and shape of discontinuities and flaws; with the ability to locate sub-surface defects and better depth penetration when compared to other NDT methods.